More than a manufacturer, we provide a one-stop solution for your business. Get in touch now!

- *Title

- *Content

Our company is currently not hiring new employees, thanks for your attention!

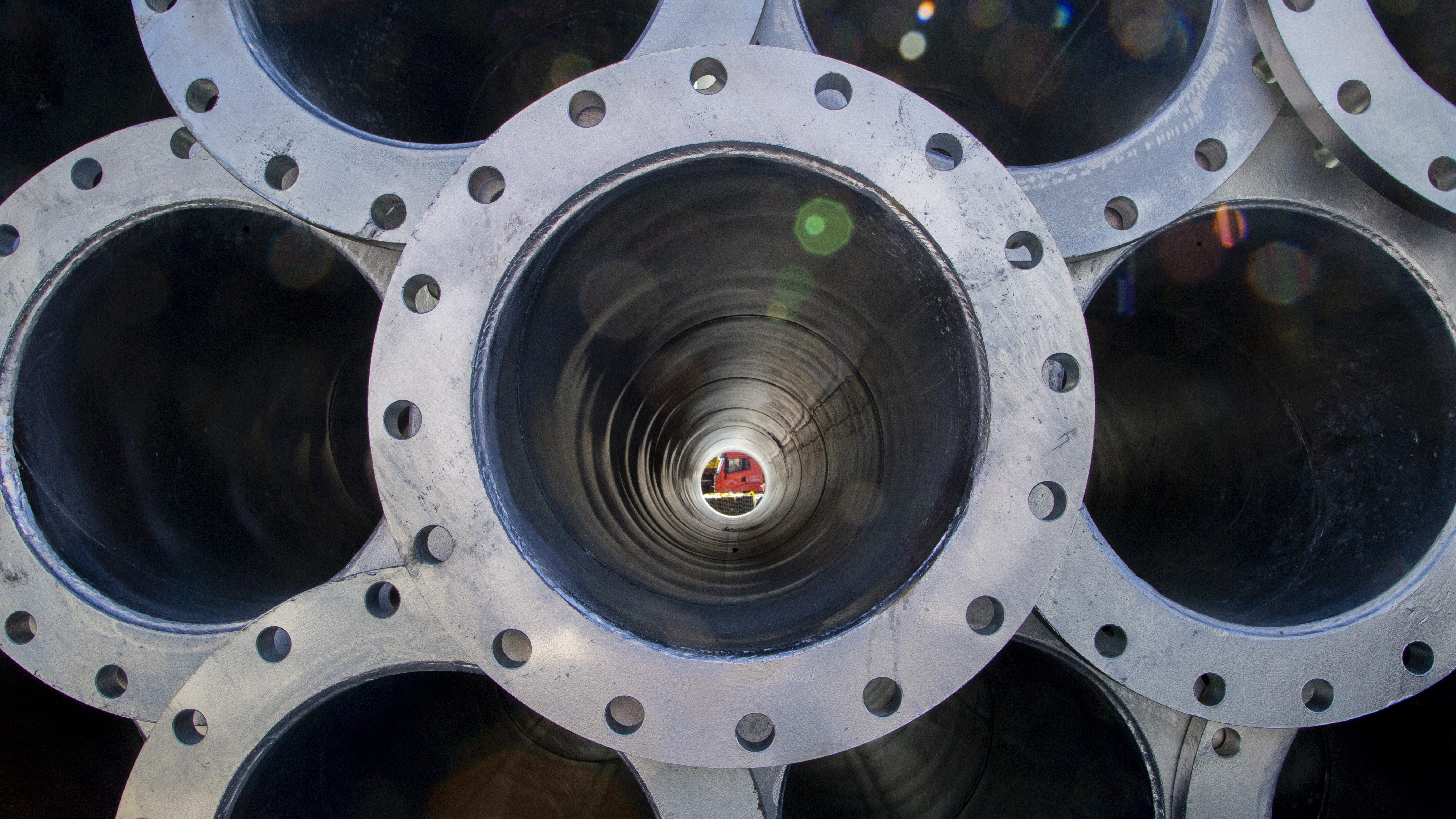

Pipe Fittings

In pipeline systems the steel pipe fittings plays an important role in transporting the liquid materials. Steel pipe fittings are often sold along with steel pipe.

Baolai Steel offers a wide range of pipe fittings in carbon steel and stainless steel which widely applied in the fields of petroleum, chemical industries, urban construction, shipbuilding, water supply and drainge, firefighting and daily life. Used to connect, control, change direction, divert, seal, and other function apart from straight pipe.

• According different body material for indsustrial pipelines, there are

Stainless steel pipe fittings/ Carbon steel pipe fittings (Black steel pipe fittings) Alloy steel pipe fittings

• According different coatings, there are

Black painted/ PE coated/ Cladding stainless steel or alloy steel/ Galvanized steel pipe fittings (zinc coated)

• According different industrial purposes, there are

Oil and gas pipelines/ Chemical plants/ Food industry/ Power stations/ Fire sprinkler pipe fittings

• According to different connection type, there

Butt weld fittings type/ Socket weld fittings type/ Threaded type/ Flanged type

Baolai Steel offers a wide range of pipe fittings in carbon steel and stainless steel which widely applied in the fields of petroleum, chemical industries, urban construction, shipbuilding, water supply and drainge, firefighting and daily life. Used to connect, control, change direction, divert, seal, and other function apart from straight pipe.

• According different body material for indsustrial pipelines, there are

Stainless steel pipe fittings/ Carbon steel pipe fittings (Black steel pipe fittings) Alloy steel pipe fittings

• According different coatings, there are

Black painted/ PE coated/ Cladding stainless steel or alloy steel/ Galvanized steel pipe fittings (zinc coated)

• According different industrial purposes, there are

Oil and gas pipelines/ Chemical plants/ Food industry/ Power stations/ Fire sprinkler pipe fittings

• According to different connection type, there

Butt weld fittings type/ Socket weld fittings type/ Threaded type/ Flanged type

0 products found

ViewShowcase

Product Description

Baolai's fittings are mainly butt-welded pipe fittings and high pressue pipe fittings. Butt-welded fittings include elbows, reducers, equal and reducing tees and couplings. We provide all painted, such as black painted, PE coated, hot dipped galvanized and so on.

Carbon Steel Buttweld Seamless Pipe Fittings are the most frequently used pipe fittings, which are the best option for pressure vessel and chemical and acid manufacturing areas. We also have carbon steel buttweld welded pipe fittings. And we also have flanges for any application.

Production Process

Fitting manufacturers create seamless construction fittings (WPB) and welded construction fittings (WPW).

In seamless construction, the steel pipe is heated and molded into its final shape. Special equipment is used to create the necessary bevels and markings. In welded construction, on the other hand, a steel plate is cut and shaped. The two sides are then welded together before they are beveled. Common steel pipe fittings include: standard butt weld fittings, socket weld fittings and threaded fittings.

Butt Weld Fittings

Butt weld fittings are required to change direction and connect to all of the other equipment and devices required to make them function. Butt weld fittings are designed with varying wall thicknesses and are beveled for welding. Butt weld fittings are constructed in both seamless and welded. The most common wall thicknesses are standard and extra heavy. Heavy wall, or special end fittings, are used for high temperature services, such as mainstream nuclear power.

Contact Person

- Name:

- Anna Zhao

- Tel:

86-13588074125

- Email:

- Anna@anndooo.com

- WhatsApp:

- https://wa.me/8613588074125

- Address:

- NO.1 XIAGUANG ROAD,NANKAI DISTRICT,TIANJIN,CHINA