More than a manufacturer, we provide a one-stop solution for your business. Get in touch now!

- *Title

- *Content

Our company is currently not hiring new employees, thanks for your attention!

Carbon Seamless Pipe

My-steel carbon Seamless steel pipe size is from 1/2"-36" with API, ASTM, BS, DIN, and JIS standards, and we have API, CE, UL, FM, and ISO certificates for quality assurance.

Seamless steel pipe is a hollow section of circular pipe without seams. Carbon Seamless Steel Pipe is made by hot rolling, cold rolling, or cold drawing, which is the common material used for oil and gas, water pipelines, construction, and boilers.

Seamless steel pipe is a hollow section of circular pipe without seams. Carbon Seamless Steel Pipe is made by hot rolling, cold rolling, or cold drawing, which is the common material used for oil and gas, water pipelines, construction, and boilers.

0 products found

ViewShowcase

Product Description

Seamless steel pipes are perforated from whole round steel, and steel pipes without welds on the surface are called seamless steel pipes. According to the production method, seamless steel pipes can be divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes.

Seamless steel pipes are mainly used as petroleum geological drilling pipes, cracking pipes for petrochemical industry, boiler pipes, bearing pipes, and high-precision structural steel pipes for automobiles, tractors, and aviation.

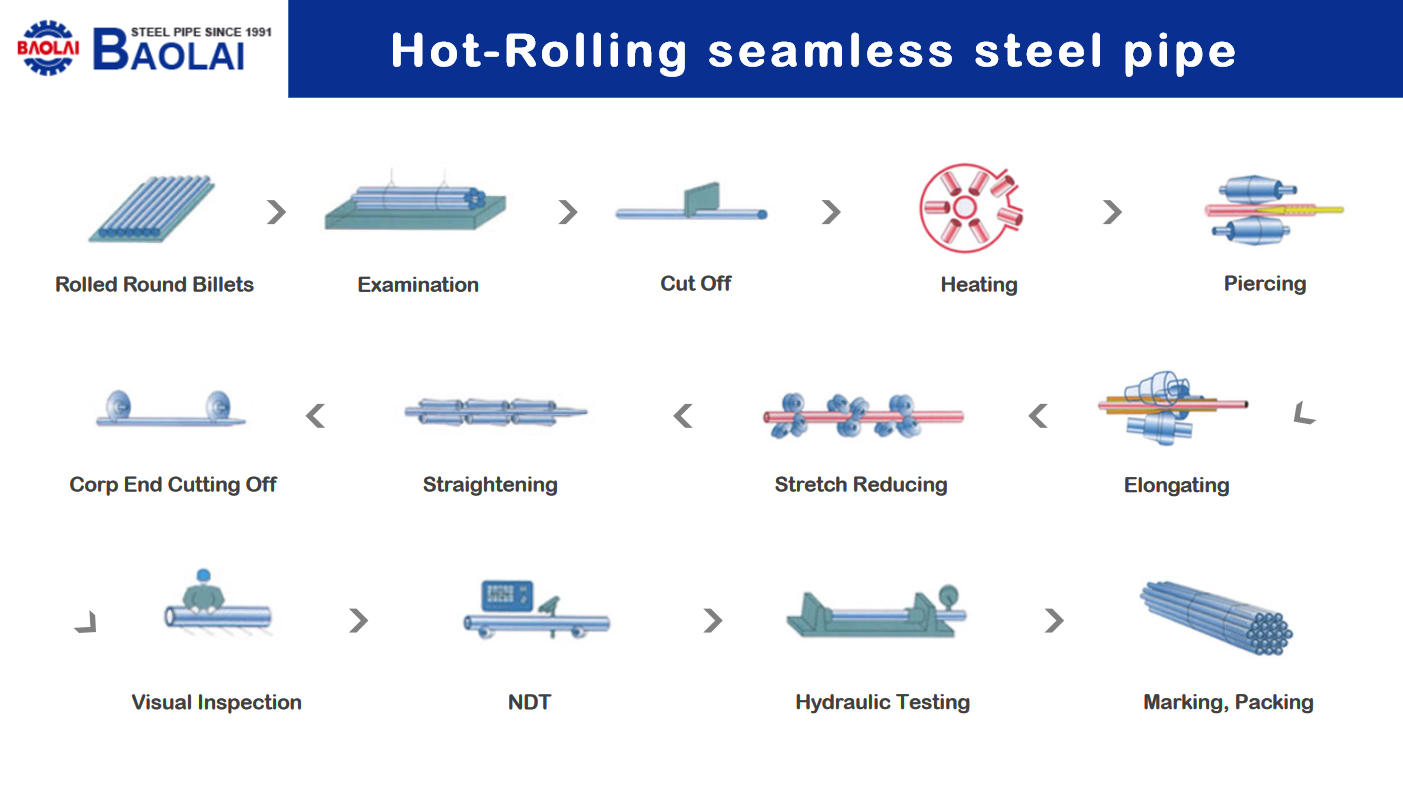

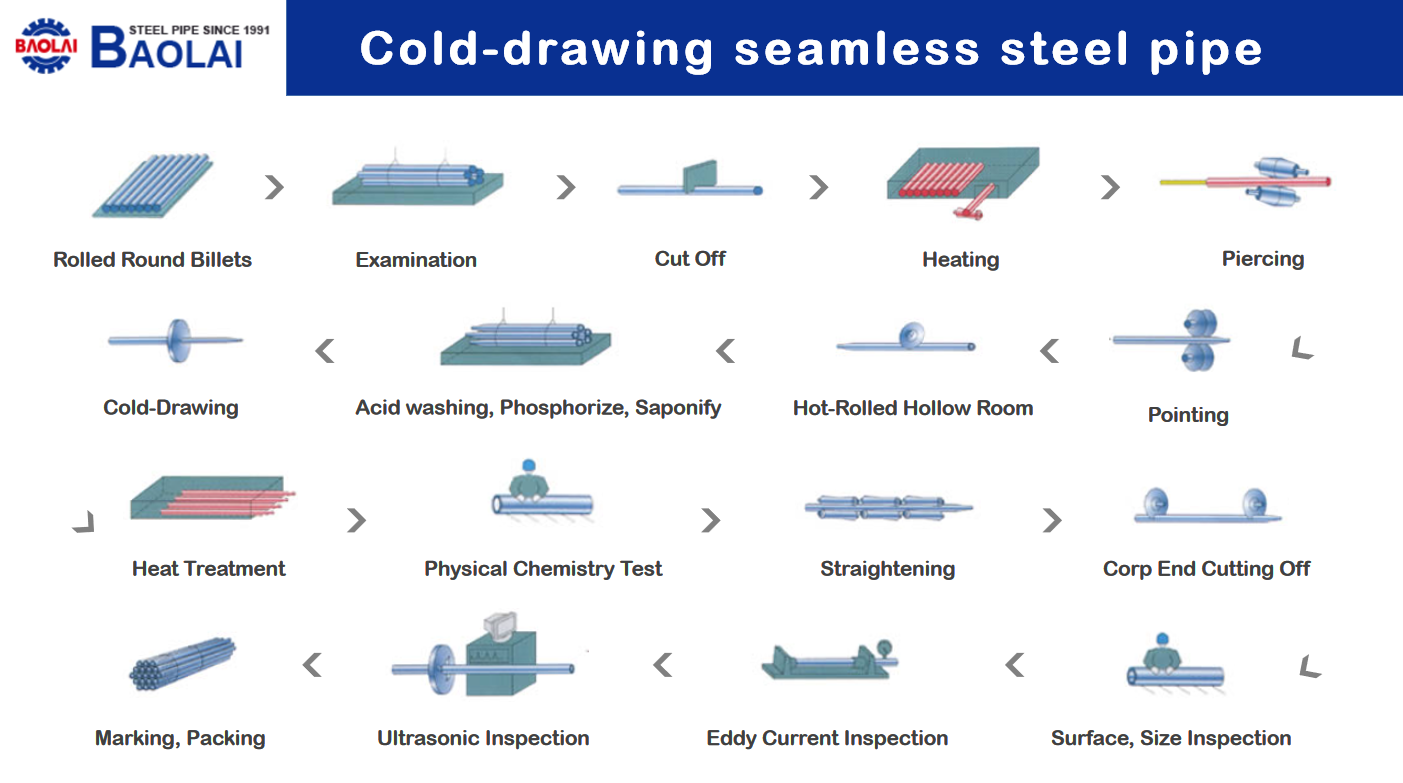

Production Process

Hot-Rolling

Hot rolling is typically not as costly or as expensive as cold rolling or cold drawing, as the steel is more malleable at a higher temperature. There is also one less step when producing the steel, which cuts back on the operating costs of producing the steel. The finish of the steel will not be as smooth or clean as cold rolled or drawn steel, and mechanical properties of the steel are typically not as good as steel in its cold drawn form. This often is not important for steel products that are produced in high quantity and do not need a clean external finish.

Cold-Drawing

Cold rolling, done often at room temperature, has the added effect of work hardening and strengthening the material thus further improving the material’s mechanical properties. It also improves the surface finish and holds tighter tolerances. However, room temperature steel is less malleable than hot steel, so cold rolling cannot reduce the thickness of a work piece as much as hot rolling in a single pass. Commonly cold-rolled products often include similar hot rolled products like sheets and bars, but are usually smaller.

Services we offer

Water Cutting

Water jet technology, also known as water jet and water cutting technology, is a real cold cutting. speed jet water cutting.

Beveling

We can apply any type of Bevel to any degree desired. Beveling can be applied to the surface of pipes of any size or diameter.

Threaded

Pipe thread is a thread located on the pipe wall for connection, mainly used for the sealing connection of water, gas, oil and other pipelines. We offer NPT* and BSPT* pipe threads.

Contact Person

- Name:

- Anna Zhao

- Tel:

86-13588074125

- Email:

- Anna@anndooo.com

- WhatsApp:

- https://wa.me/8613588074125

- Address:

- NO.1 XIAGUANG ROAD,NANKAI DISTRICT,TIANJIN,CHINA